Lionel MURAT

Lionel is co-founder of CIKLab. Former quality control manager with expertise in third-party food testing and laboratory management.

You work in food quality control and you’re still using Excel to manage all your testing analyses? I get it. I did that for years before creating CIKLab. And I know exactly what you’re dealing with on a daily basis.

Today, I’m going to explain why we developed CIKLab and how it can transform your quality control management, a real field experience.

CIKLab is a SaaS food quality control software designed to manage all your testing operations, from product and supplier monitoring plans to certificate of analysis (CoA) generation, including complete batch and analysis management.

When I was a quality control manager in the food industry, I spent countless hours every week juggling:

One day, while talking with colleagues, I realized I wasn’t the only one struggling: many quality and control managers were experiencing the same thing. There simply wasn’t a truly adapted solution—between lab-wired LIMS and ERPs not designed for operational quality control management, we were all improvising.

When I did the math, I realized we were wasting enormous amounts of time creating, modifying, and managing dozens of Excel files trying to stay organized and anticipate problems as best we could.

That’s when the idea for CIKLab was born.

Don’t get me wrong, my partner and I often say this, Excel is an amazing tool! Who could claim otherwise? But it’s not a management tool, and certainly not for handling all dimensions of food quality control.

Excel can quickly show its limitations:

Real-life example: One of our clients now using CIKLab told us that someone in the company had developed a great Excel system with many file linkages and macros to make the process smooth, but after that person left and with Excel updates, the system “crashed”—no one was able to get it working again.

CIKLab wasn’t developed by IT professionals. It was designed and conceived by quality managers who understand the organization and constraints of the field.

The result? An interface where you find information in 2 clicks maximum. No need to open a cascade of windows to access info, no need for 3 days of training to understand how it works.

When you create a batch, everything is there:

Our experience: Our new users are autonomous in less than an hour. Because the interface matches their way of working, not the other way around.

Implementing new software is very impactful! And it can be a real source of anxiety. “What if I made a mistake? What if it doesn’t work? And training the team?”

At CIKLab, we support you from start to finish:

In practice: A new client is operational in less than 2 weeks. And we remain available afterward to support you during adoption.

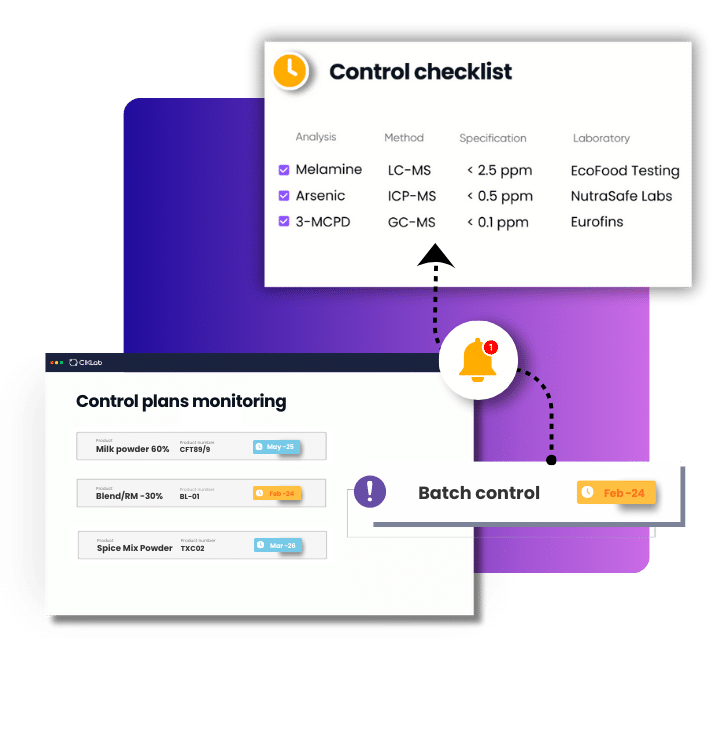

Control plans are the backbone of a quality department.

No coherent batch and manufacturing management is possible without effective planning. In practice in the industry, these are actually hundreds of control plans and specifications to manage, maintain, and keep up to date.

With CIKLab, you create your control plan once, and the software does the rest.

Practical example: You manufacture a dietary supplement that requires:

You set this up once in CIKLab using inspection templates. With each new batch, the application automatically tells you which analyses to order based on frequencies. No more wondering “when’s the next heavy metals analysis again?” “What were the last results?”

The benefit: You never miss an analysis again, you save considerable time on planning, and you access dates and results history in real time. CIKLab perfectly addresses chapter 2.5.9 of FSSC 22000.

This is clearly something other software struggles to handle, yet outsourcing analyses is essential in food testing. All food, ingredient, cosmetic, and dietary supplement manufacturers outsource a very large portion of analyses.

And that’s where it gets complicated:

CIKLab centralizes and simplifies all that:

Real case: Many of our clients work with about ten different laboratories. Before CIKLab, they lost hours per week checking prices on quotes, verifying methods, and testing turnaround times. Now? It’s configured based on products or matrices and automated.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Certificate of analysis generation is the bottleneck for the testing department.

Before issuing the precious document, you need to:

With CIKLab:

The benefit: One of our latest clients saved the equivalent of one full-time annual position on certificate generation alone!

Your results are your analytical asset, a goldmine of information. But how many of us truly leverage this data? It’s very difficult to search and retrieve information from dozens of files; many don’t even enter results but often just compliant/non-compliant, making it impossible in those cases to evaluate trends or detect weak signals.

With Excel, it’s complicated to have a clear view.

With CIKLab, you have:

Concrete example: By visualizing the history of microbiological analyses over several months and different batches, one of our clients detected a progressive drift. Upon investigation, it was linked to a biofilm developing on equipment. Early detection = quick correction = no crisis.

In food processing, data security is central. Your quality control analyses are your proof of compliance in case of audit or crisis.

CIKLab means:

Your data is more secure in CIKLab than in Excel files or on your local server!

For audits: All your data is timestamped and traceable. No more panic when the auditor asks “show me the history of this batch,” “who entered or modified this result?” “Show me that only authorized people can sign a certificate?”

CIKLab is designed for professionals who need to manage quality control analyses and external analyses across multiple control plans.

Step 1: Batch creation

You launch production or receive raw material: you create the batch in CIKLab in 3 seconds, or automatically with API-ERP connection.

➡️ CIKLab automatically displays the tests to perform according to your control plan.

Step 2: Ordering analyses

CIKLab indicates the analyses to launch and pre-selected laboratories. In 1 click, you order all external and internal analyses.

CIKLab generates:

Step 3: Real-time monitoring

You see at a glance:

Step 4: Results reception

Laboratories send you their reports. You can import them into CIKLab (drag & drop the PDF, or automatic import) and automatically link them to batches (no more need for folder trees on your network).

Step 5: Batch release

If everything is compliant, you validate batch release. CIKLab can automatically generate:

Step 6: Archiving and traceability

Everything is automatically archived, timestamped, and traceable in the application’s audit trail. In case of audit or complaint, you find all information in seconds.

Our clients observe on average:

Before investing in software like CIKLab, ask yourself the right questions:

1. What’s your testing volume? If you do 2 batches per month with 3 analyses on a few control plans, Excel probably suffices. If you do 50 batches per month with 15 analyses each, with multiple monitoring plans, then CIKLab will change your life!

2. How much time do you lose on administrative management? Do the math, but do it honestly: time spent managing Excel, updating control plans, editing multiple technical sheets, ordering analyses, tracking deadlines, generating CoAs… If it’s more than 5 hours per week, CIKLab already pays for itself!

3. Do you have traceability problems or recurring errors? Difficult to find an analysis result? Uncertainty about a batch status? CIKLab solves these problems.

4. Are you ready to digitalize? Software changes habits. The team needs to be ready to abandon Excel for a new system.

My partner and I created CIKLab because we desperately needed it when we worked in the industry. Every day, I see that our prospects still have the same issues we had:

CIKLab isn’t miracle software. It’s a pragmatic tool that addresses real food quality control problems. No frills, no gimmick features, just what you need.

My advice: If you recognize yourself in the issues described in this article, request a demo. We’ll show you concretely how CIKLab can adapt to your situation.

Lionel is co-founder of CIKLab. Former quality control manager with expertise in third-party food testing and laboratory management.

You work in food quality control and you’re still using Excel to manage all your...